NEWS

DEVOTED ELABORATE RIGOROUS HARMONIOUS

![]() HOME-NEWS-Liming Heavy Industry new

HOME-NEWS-Liming Heavy Industry new

Advantages and applications of S5X circular vibrating screen

24/10/2025

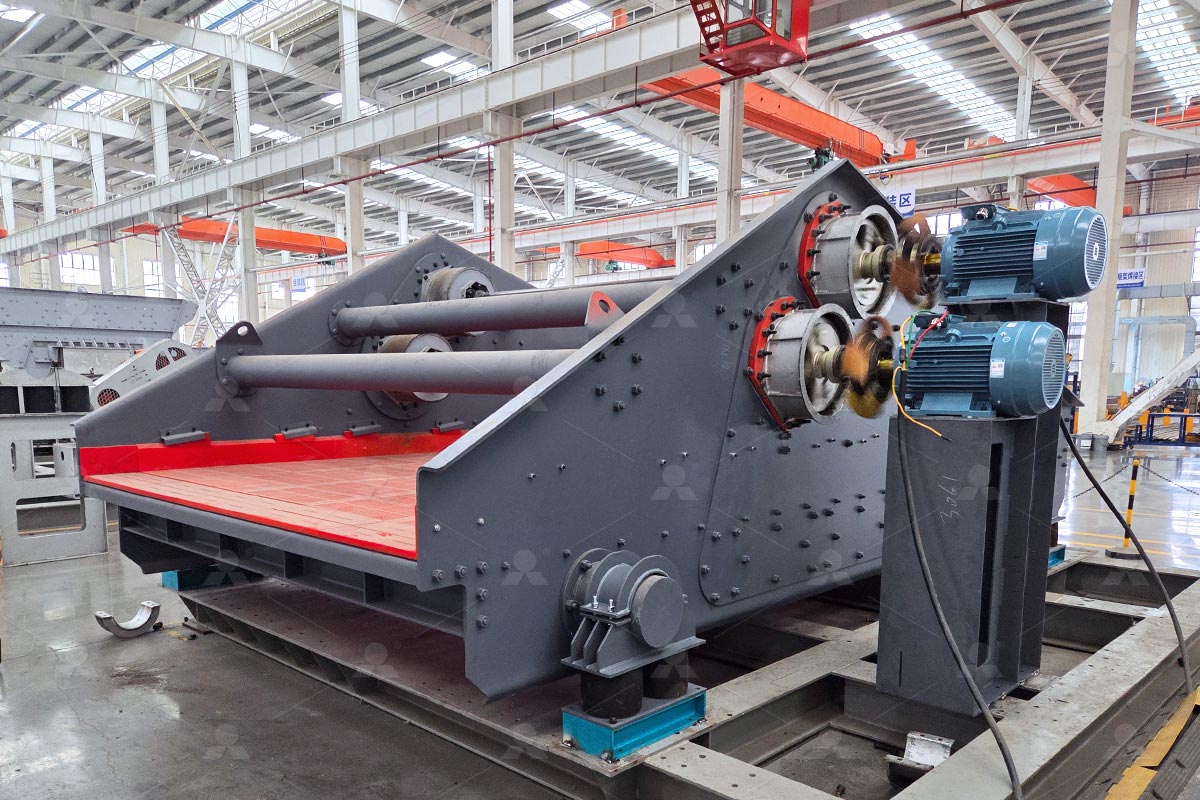

The S5X Circular Vibrating Screen: Liming Heavy Industry’s Pioneering Solution for High-Efficiency Material Classification

In the dynamic landscape of mineral processing, construction aggregates, and industrial material handling, efficient classification stands as a cornerstone of operational success. As a global leader in crushing, screening, and mineral processing equipment, Liming Heavy Industry has long been committed to developing innovative technologies that redefine industry standards. The S5X Circular Vibrating Screen—a flagship product in our screening equipment lineup—epitomizes this commitment, integrating advanced engineering, robust construction, and intelligent design to deliver unmatched performance, reliability, and cost-effectiveness for clients worldwide.

1. Introduction: The Critical Role of Screening and Liming’s Innovation Mission

Screening, the process of separating solid materials into distinct particle size fractions, is indispensable across a spectrum of industries. From quarries producing construction aggregates to mineral processing plants extracting valuable ores, and from coal preparation facilities to chemical processing units, precise classification directly impacts product quality, production efficiency, and downstream process performance. A subpar screening solution can lead to wasted raw materials, inconsistent end products, increased energy consumption, and costly equipment downtime—challenges that modern enterprises cannot afford in an era of intensifying market competition.

For over three decades, Liming Heavy Industry has focused on addressing these industry pain points through continuous R&D and technological iteration. Our core mission—“To Provide Global Clients with High-Quality Crushing & Screening Solutions”—drives every stage of product development, from concept design to after-sales support. The S5X Circular Vibrating Screen is the result of this mission: a device engineered to overcome the limitations of traditional screening equipment, such as low processing capacity, poor screening accuracy, high noise, and short service life. By leveraging advanced dynamics principles, high-strength materials, and intelligent optimization, the S5X sets a new benchmark for circular vibrating screens, catering to the evolving needs of industries ranging from mining and construction to metallurgy and environmental protection.

2. Core Working Principle: The Science Behind the S5X’s Superior Performance

At the heart of the S5X Circular Vibrating Screen’s efficiency lies its advanced working principle, which combines eccentric vibration drive with optimized screen surface motion to achieve precise, high-speed material classification. Unlike conventional screens that rely on simple linear or low-amplitude vibration, the S5X utilizes a circular motion trajectory—engineered to maximize material stratification and particle penetration—ensuring that even fine or sticky materials are screened effectively.

2.1 Eccentric Vibration Drive System

The S5X is powered by a high-performance eccentric shaft assembly, composed of a precision-machined eccentric shaft, high-quality bearings, and a sealed housing. When the motor (connected via a flexible coupling to minimize vibration transmission) drives the eccentric shaft to rotate, the unbalanced centrifugal force generated by the eccentric weights creates a circular vibration of the screen box. This centrifugal force is precisely calibrated: too weak, and materials may not stratify or move forward; too strong, and energy is wasted, leading to excessive wear. Liming’s R&D team has optimized the eccentric distance and weight distribution of the shaft to match different material properties (e.g., density, particle size, moisture content), ensuring optimal vibration intensity for every application.

2.2 Material Stratification and Screening Process

The circular vibration of the screen box drives the material on the screen surface through a three-stage motion cycle, critical for efficient classification:

1.Stratification: As the screen box vibrates, larger particles are thrown upward and outward by the centrifugal force, while smaller particles sink to the bottom layer—closer to the screen surface. This stratification eliminates the “blocking” of screen holes by large particles, a common issue in traditional screens that reduces throughput.

2.Forward Transport: The circular motion also imparts a continuous forward momentum to the material, ensuring a steady flow across the screen surface without stagnation. The angle of the screen box (adjustable between 15°–25°) further optimizes this transport speed, balancing processing capacity and screening accuracy.

3.Particle Penetration: Smaller particles (meeting the target size) pass through the screen holes into the lower collection hoppers, while oversize particles continue moving forward to the discharge end. This process is repeated across multiple screen layers (the S5X can be configured with 1–5 layers), enabling simultaneous classification of multiple particle size fractions in a single pass.

2.3 Key Advantages of the Circular Motion Design

Compared to linear vibrating screens or high-frequency screens, the S5X’s circular motion offers three distinct benefits:

•Higher Throughput: The combination of stratification and forward transport allows the S5X to process up to 30% more material than linear screens of the same size, making it ideal for large-scale production lines.

•Better Accuracy: The controlled circular trajectory ensures that particles have more opportunities to contact the screen surface, reducing the risk of undersized particles being carried over with oversize material (known as “misclassification”).

•Adaptability to Sticky Materials: For materials with high moisture content (e.g., clayey ores, wet sand), the circular vibration helps break up agglomerates, preventing screen hole clogging and maintaining consistent performance.

3. Structural Design: Robustness, Durability, and User-Friendliness

The S5X Circular Vibrating Screen’s structural design is a testament to Liming’s focus on long-term reliability and operational convenience. Every component—from the screen box to the damping system—is engineered to withstand harsh industrial environments (e.g., heavy loads, dust, temperature fluctuations) while minimizing maintenance requirements.

3.1 High-Strength Screen Box

The screen box, the core load-bearing component of the S5X, is constructed using Q355B high-strength structural steel—a material renowned for its excellent impact resistance and fatigue strength. Liming employs a welded structure with full penetration welds (inspected via ultrasonic testing) to ensure the screen box can withstand the continuous vibration and material impact without deformation or cracking. Additionally, the inner surface of the screen box is lined with wear-resistant rubber plates, which not only protect the steel structure from abrasion but also reduce noise (by absorbing vibration energy) and prevent material adhesion.

To further enhance durability, the screen box’s side plates are reinforced with ribbed steel plates at key stress points (e.g., near the eccentric shaft bearings, discharge end). This reinforcement design has been validated through finite element analysis (FEA) and field testing, ensuring the screen box can operate continuously for over 8,000 hours per year without structural failure.

3.2 Optimized Screen Surface and Frame

The screen surface is the “working face” of the S5X, and its design directly impacts screening efficiency and service life. Liming offers three screen surface options to match different application needs:

•Woven Wire Mesh: Ideal for dry, non-abrasive materials (e.g., coal, limestone aggregates). Made of high-carbon steel or stainless steel, the mesh has precise hole sizes (ranging from 0.1mm to 150mm) and high tensile strength, ensuring minimal deformation under vibration.

•Polyurethane Mesh: Suitable for abrasive or wet materials (e.g., iron ore, copper ore, wet sand). Polyurethane’s high wear resistance (3–5 times that of steel mesh) and elasticity prevent clogging, while its light weight reduces the load on the screen box.

•Perforated Steel Plate: Used for coarse screening of large, heavy particles (e.g., boulders, ore lumps). The plate is thick (6–12mm) and features tapered holes (wider on the top, narrower on the bottom) to facilitate particle penetration and prevent blockage.

The screen surface is fixed to the screen frame using a quick-release clamp system, developed by Liming to simplify replacement. Unlike traditional bolted systems (which require tools and 30+ minutes per replacement), the quick-release clamps allow operators to change the screen surface in 5–10 minutes—significantly reducing downtime and labor costs.

3.3 Damping System: Stability and Vibration Isolation

Vibration is essential for screening, but excessive vibration transmission to the foundation can damage the production line and create safety hazards. The S5X is equipped with a high-performance rubber damping spring system, which absorbs up to 95% of the screen box’s vibration energy, preventing it from spreading to the frame and foundation.

The damping springs are made of natural rubber with high elasticity and aging resistance (tested to maintain performance for over 5 years in harsh conditions). They are arranged symmetrically under the screen box, ensuring balanced load distribution and stable operation even at maximum throughput. Additionally, the spring seats are made of cast iron with a corrosion-resistant coating, further extending the system’s service life.

3.4 Drive System: Efficiency and Low Maintenance

The S5X’s drive system is designed for reliability and ease of maintenance. Key components include:

•High-Efficiency Motor: Equipped with a Y-series three-phase asynchronous motor (IP54/IP55 protection class), which has an efficiency rating of over 90% (exceeding IE2 standards). The motor is dustproof and waterproof, suitable for outdoor or dusty environments.

•Flexible Coupling: Connects the motor to the eccentric shaft, absorbing vibration and reducing wear on both components. The coupling uses high-quality rubber diaphragms, which require no lubrication and have a service life of over 2 years.

•Sealed Bearing Housing: The eccentric shaft’s bearings are housed in a sealed, oil-lubricated chamber. The seal (double-lip oil seal + dust seal) prevents dust and water from entering, while the oil bath lubrication ensures continuous lubrication—extending bearing life to over 8,000 hours.

4. Performance Advantages: Why the S5X Outperforms Competitors

4.1 Higher Screening Efficiency and Accuracy

4.2 Larger Processing Capacity

4.3 Longer Service Life and Lower Maintenance Costs

4.4 Low Noise and Environmental Friendliness

<<Previous: The Core Role of Crushing in Copper Ore Processing >>Next: Liming Heavy Industry Drives a New Future of Industrial Value

Contact Us

Our professional engineer team has started a global customer visit , to provide customers with omni-directional and heart to heart on-site service.

Whether you are using our equipment or not, welcome to leave online message and get in touch with us,

we will be glad to provide you with a variety of material processing technologies and complete equipment solutions in the first time.