NEWS

DEVOTED ELABORATE RIGOROUS HARMONIOUS

![]() HOME-NEWS-Liming Heavy Industry new

HOME-NEWS-Liming Heavy Industry new

Silica Sand Processing Plant

29/10/2022

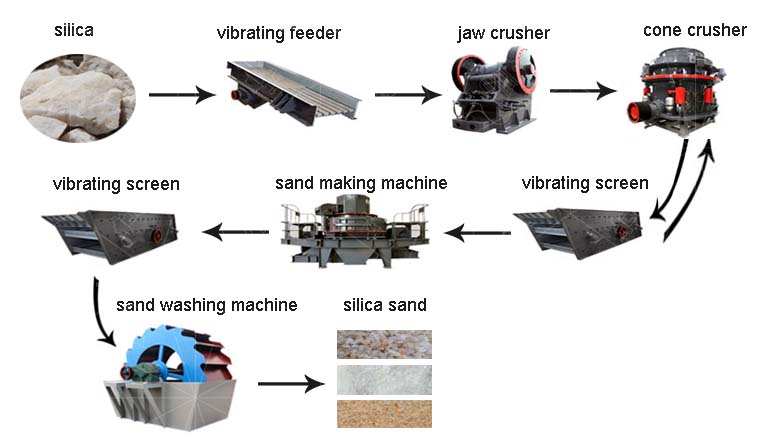

Silica sand process flow

Crushing:

The mined silica sand (quartz sand) ore is continuously fed into the coarse jaw crusher by the vibrating feeder for primary crushing, and then the particles after primary crushing are sent to the fine jaw crusher by the belt conveyor for re-crushing, and the crushed silica sand particles are sent to the vibrating screen for screening and grading.

Sand making:

After the screening process, the quartz sand particles that meet the feeding particle size requirements of the vertical shaft impact crusher enter the sand making machine for sand making process, and those that do not meet the requirements are returned to the crusher for re-crushing.

Screening:

The qualified silica sand particles from the sand making machine are returned to the circular vibrating screen for re-screening, the materials that meet the requirements go to the next process, and the materials that do not meet the requirements are returned to the sand making machine for sand making and crushing again;

Sand washing:

The produced silica sand is sent to the sand washing machine by the belt conveyor for cleaning, and the cleaned silica sand is sent to the finished product pile.

Advantages of the processing plant

1. Reasonable equipment configuration, advanced manufacturing technology, reliable quality, wear-resistant wearing parts and long service life.

2 The failure rate, total energy consumption and power consumption during operation are relatively low, and the operating cost can be reduced by more than 50%.

3 Equipped with a pulse dust collector, there will be no dust pollution problem during operation, and the low-carbon environmental protection effect is more significant.

4 The price of the whole production line is very economical and the after-sale service is more perfect. It is a production line with high application value in the market.

Silica sand processing plant equipment

Silica sand is produced by a series of crushing and sand-making treatment of large pieces of quartz stone into finished sand of various specifications. The silica sand production line equipment recommends jaw crusher, cone crusher, vertical shaft impact crusher (sand making machine) and wheel bucket sand washing machine etc.

1. Coarse crushing:

The texture of quartz stone is very hard, and the efficiency of sand making directly is not high, and the damage to the sand making equipment is relatively large, so we need jaw crusher as coarse crushing equipment. The primary crushing of the jaw crusher can make all kinds of block-shaped quartz stone uniform in particle size, which can meet the requirements of the feed opening of the sand making machine, with large output, large crushing ratio, uniform product particle size, and low equipment price and low investment cost.

2. Medium and fine crushing:

The cone crusher is adopted, it has new crusher structure and optimized laminated crushing cavity, which makes the production capacity large and the crushing efficiency high. In addition, it also has the characteristics of automation and intelligence, high production safety and good environmental performance. It is suitable for hard materials and high output requirements.

3. Fine crushing:

Adopt sand making machine as the fine crushing equipment. The feeding size is below 50mm, and the output size can reach 0-5mm. It is more suitable for shaping and sand making of silica sand. It has a variety of cavity types. Higher efficiency, energy saving and environmental protection, and the finished product has a uniform particle size, the particle size is about 30 mesh, and the needle flake content is low.

<<Previous: Lithium mine extraction process >>Next: Calcium carbonate milling process (20-3250 mesh)

Contact Us

Our professional engineer team has started a global customer visit , to provide customers with omni-directional and heart to heart on-site service.

Whether you are using our equipment or not, welcome to leave online message and get in touch with us,

we will be glad to provide you with a variety of material processing technologies and complete equipment solutions in the first time.