NEWS

DEVOTED ELABORATE RIGOROUS HARMONIOUS

![]() HOME-NEWS-Liming Heavy Industry new

HOME-NEWS-Liming Heavy Industry new

Lithium Lepidolite production of lithium carbonate

14/07/2022

1. Comprehensive utilization of brine: The lithium ingredients and liquid after extracting the chloride after extracting the chloride is extracted to remove the calcium and magnesium ions in the ingredients, add acidic acidization of hydrochloride, evaporates sodium chloride, then removes the iron, and then adds excessive solid alkali Make lithium carbonate precipitates, is washed, centrifugal, and dry, and lithium carbonate products are made.

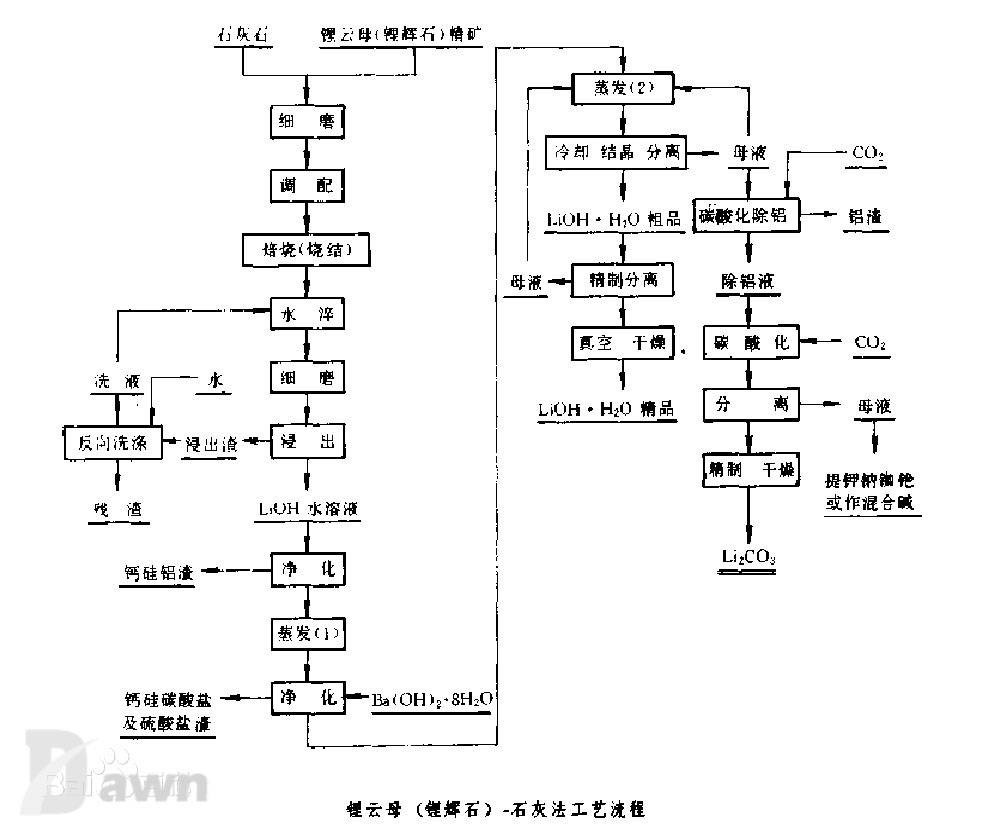

2. Lime sintering method: Splendin concentrate (6%containing lithium oxide) and limestone by 1: (2. 5 ~ 3) weight ratio ratio. Mixed grinding, fired lithium aluminum and calcium silicate at 1150 ~ 1250 C, crushed through wet grinding, immersed lithium hydroxide with a lotion, filtered by sinking, filtering or washing residue, evaporation and concentration of immersion liquid, and then transparent and concentrated, then Add sodium carbonate to generate lithium carbonate, and then separate and dry it by centrifugation. Compared with lithium sulfuric acid method, the lime sintering method has the advantages of the advantages of simple processes, valuable chemical raw materials, and products with extensive use of products.

3. Use lithium hydroxide and carbon dioxide as the raw material to react with high purity lithium carbonate, or lithium sulfate and sodium carbonate as the reaction. , Generally about 75%, and the product also contains a small amount of lithium sulfate.

4. Sulfuric acid method: The melting hypalole reacts with sulfuric acid, and then purifies it with sodium carbonate reactions.

5. Lime method: The baked liquid pylorus reacts with the lime milk, and then the reaction with sodium carbonate is purified.

6. Taking lithium hydroxide as the raw material, after heating water dissolves it, the insoluble object is filtered, and the clean carbon dioxide gas is passed into the hot filter fluid until the precipitation is not reappeared. To pass, just dry at 110C. Solk industrial lithium carbonate in cold water. After filtering, the filter liquid is boiled and stops heating. It is washed, dried, and dry while hot water.

<<Previous: Pebble stone crushing technology >>Next: Extraction of Lithium from Lepidolite with a grinding mill

Contact Us

Our professional engineer team has started a global customer visit , to provide customers with omni-directional and heart to heart on-site service.

Whether you are using our equipment or not, welcome to leave online message and get in touch with us,

we will be glad to provide you with a variety of material processing technologies and complete equipment solutions in the first time.