Mongolia Mining 2023 International Mining & Oil Expo will be held for the 12th consecutive year on 3rd-5th October 2023 at Buyant Ukhaa Sport Palace, Ulaanbaatar, Mongolia. The 12th edition of the expo will feature traditional mining and emerging oil industries of Mongolia with exhibitors and visitors representing the industry's major companies and the largest number of professionals.

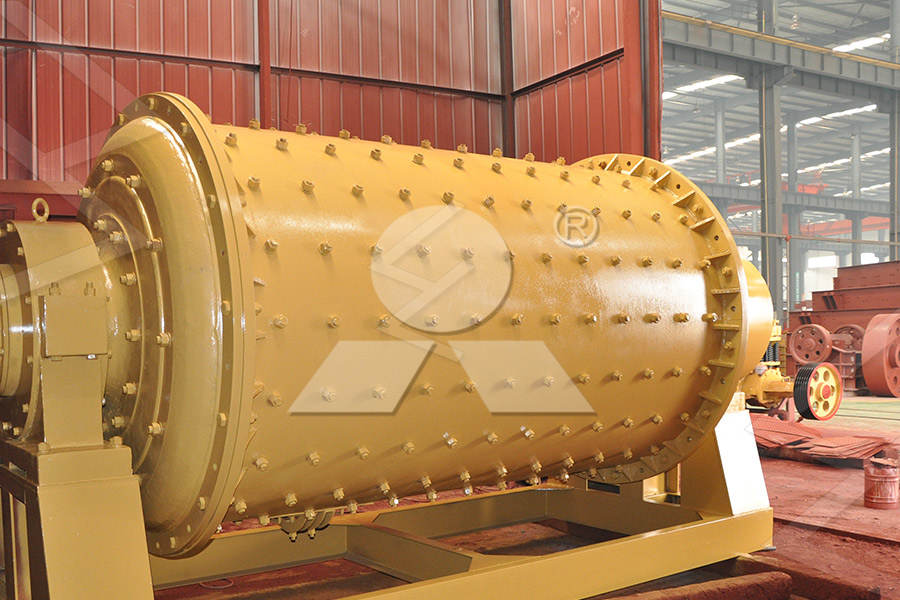

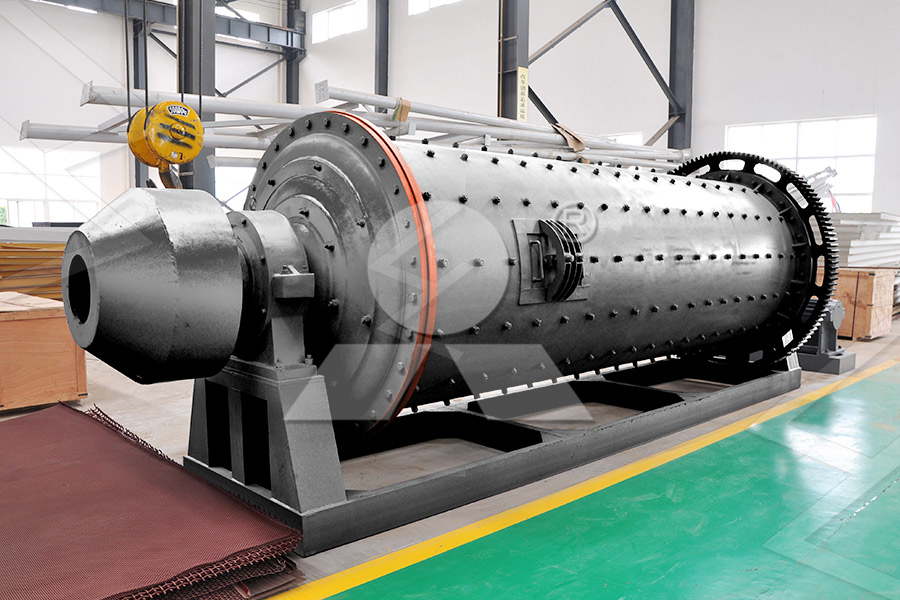

Liming is participating in Mongolia Mining 2023 International Mining & Oil Expo.Welcome to our booth to know more details about stone crusher,grinding mill or mobile crusher.

Title: Mongolia Mining 2023 International Mining & Oil Expo

Date: October 3rd-5th, 2023

Booth No.: C02

Venue: Buyant Ukhaa Sport Palace,Ulaanbaatar,Mongolia

Contact: Edward

Tel: 0086 15937123817

Whatsapp: 0086 17530851892