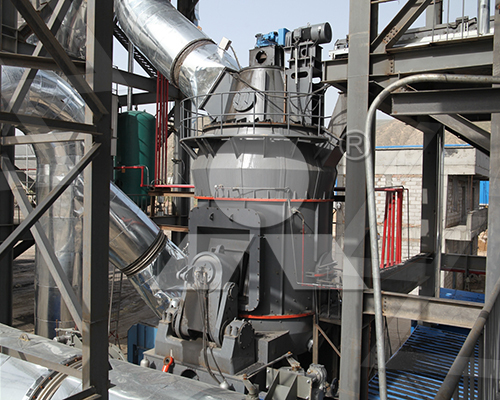

Grinding mill in clean pulverized coal production line

In the clean pulverized coal production line, grinding mill is the key equipment to ensure the fineness and quality of the produced coal powder. Liming recommends LM vertical roller mill and MTW series trapezium grinding mill for clean coal powder grinding process.

LM series vertical roller mill

-- One step preparation process - drying while grinding

LM vertical roller mill grinding system is the core of the clean pulverized coal production line. It integrates crushing, drying, grinding, and grading transportation, and achieves a one-step pulverization process of grinding and drying at the same time. This large-scale grinding equipment has condensed stable technological elements, equipped with a CO/O2 online analysis system, grinding roller hydraulic device, and automated electronic control device, making the entire grinding process intelligent, convenient, energy-saving, and environmentally friendly.

Application scope: It is suitable for users who require large output of pulverized coal and petroleum coke powder.

Processing capacity range: 5-100T/H

Advantages:

Leading technology

The LM vertical roller mill has simple process, integrating crushing, drying, grinding, powder selection and transportation, with a compact layout and small floor area, reducing civil engineering and equipment investment. It adopts the principle of material layer grinding and the automatic pressure technology of grinding rollers, the efficiency is high.

Low operating costs

The equipment is easy to operate and has a hydraulic roller flipping device. During maintenance, the grinding roller can be completely flipped out of the machine, making maintenance convenient. At the same time, the grinding roller adopts thin oil automatic lubrication system, which does not require manual labor and has low operating and maintenance costs.

High degree of automation

Adopting fully automatic control system, remote control can be achieved, and the operation is simple and easy.

Efficient and environmentally friendly

The entire system operates under negative pressure, without dust overflow, with high grinding efficiency and low energy consumption. Compared with traditional Raymond mill and ball mill, it can save 40% -50% of power consumption.

Large production capacity, wide adaptability, and simple operation

Liming LM vertical roller mill has the advantages of large output, wide adaptability, simple operation, rapid adjustment, low maintenance cost, and energy conservation, making it a priority choice for clean pulverized coal production.

Safety

The entire system has explosion-proof measures to minimize accidents and ensure on-site safety production for customers.