With the continuous development of the mining industry, the demand for crushers is also growing, and there are many crusher manufacturers in the market, the types of crushing equipment are complex, how to distinguish the advantages and disadvantages of crushers has become a problem, but the following five aspects can help you solve this problem.

1, crusher Material

Generally speaking, the main raw material of the crusher is steel. So when judging the quality of crusher, first look at the steel. The same crusher, the different steel directly determines the quality of crusher and directly affects the price of the crusher. Generally, good steel looks heavier. The key is to judge by experience.

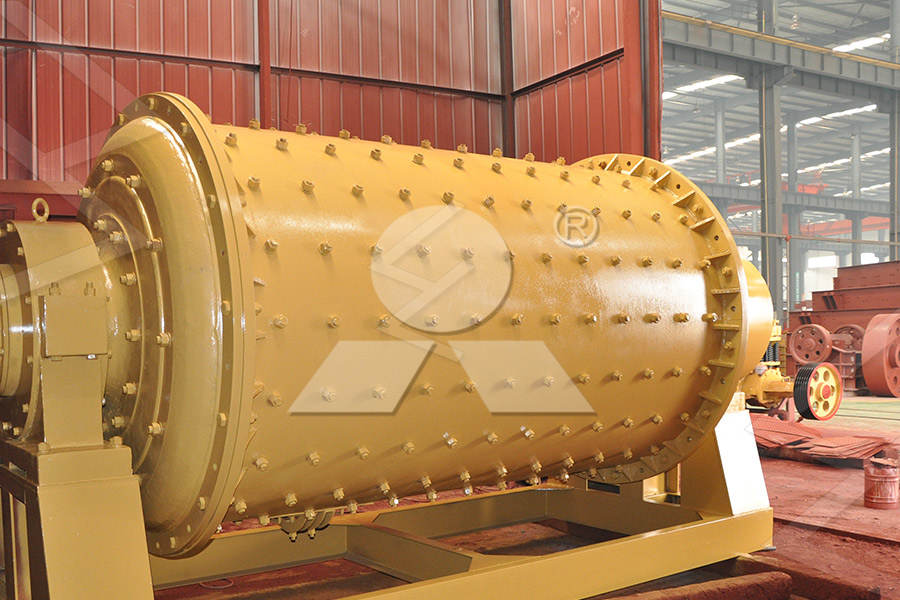

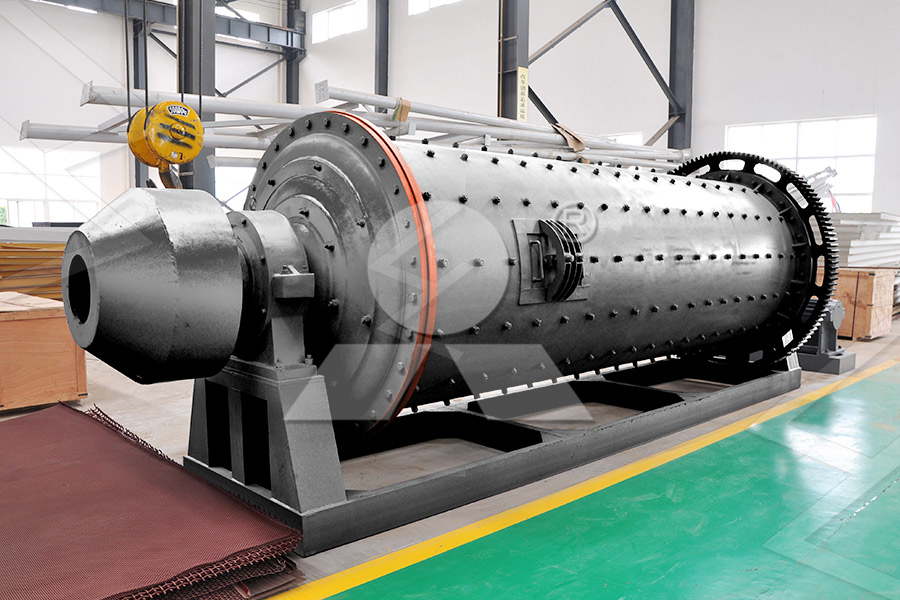

2, crusher work

Mainly depends on the crusher equipment itself structure and shape, and some details, such as whether the steel plate welding is smooth, clean, seamless. Because the crusher internal material movement speed is high, the pressure is strong, if there is a gap will lead to the gap will become larger, so as to shorten the crusher life.

3, crusher price Price is the embodiment of value. Crusher price is proportional to crusher quality. A crusher with a slightly higher price will have better quality under normal conditions. Therefore, customers should not only pay attention to price but ignore crusher quality when choosing crusher. They should not be greedy for cheap and suffer heavy losses.

4, the strength of crusher manufacturers

The strength of crusher manufacturers mainly refers to the comprehensive strength of economic strength, technical strength, and professional ability. When choosing crusher, customers should fully understand the comprehensive situation of the crusher manufacturer. When conditions permit, it is better to visit the crusher manufacturer and inspect its scale, workshop, production site, etc. Strong enterprises can produce better quality crushing equipment. In addition, you can also go to his customer site to understand the operation of crusher equipment, listen to customer evaluation of equipment. The quality of customer evaluation is assured.

5, crusher after-sales service

Speaking of after-sales, this is closely related to the choice of manufacturers, it is best to choose large professional crusher manufacturers after the sale is guaranteed. General small crusher manufacturers can only provide short-term warranty service because they do not guarantee the quality of their products.