Compared with natural sand stone, artificial sand stone is widely used for its advantages of rich material sources, little seasonal impact on processing, good grain shape and grading of finished materials, enhanced concrete strength and reduced cement consumption.

In the design of artificial sand and stone system, sand making technology is the key. How to choose the right production technology to ensure the reliable operation, advanced technology and reasonable economy of the processing system is still an important problem in the design of the artificial sandstone processing system. This article introduces three kinds of sand making processes which are widely used at present.

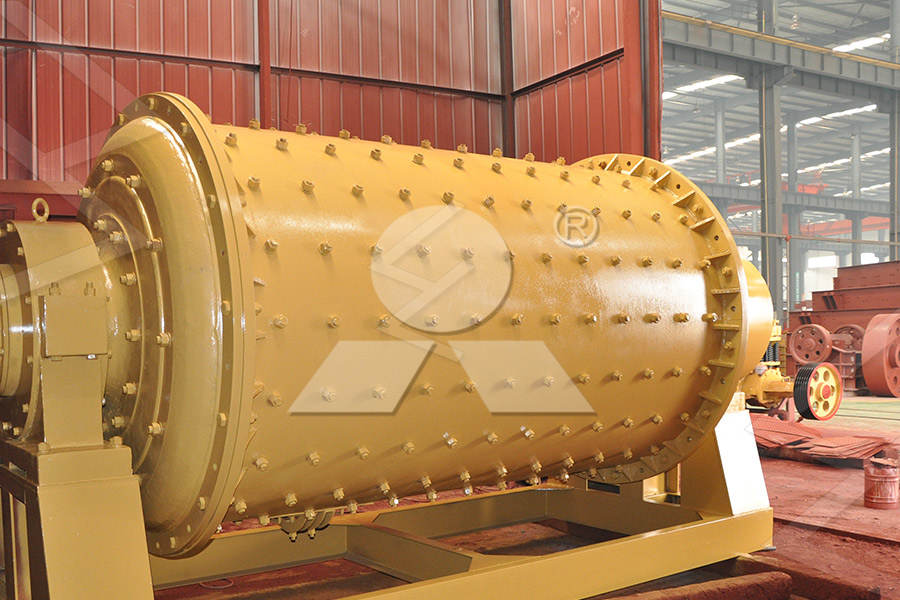

1. Technology Of Rod Grinding Machine-Made Sand

The particle size distribution of artificial sand rolled by rod mill has a certain rule, that is, one kind of fineness modulus has only one kind of particle size gradation. Therefore, in the production of artificial sand, it is necessary to control the stability of fineness modulus, and the grading of its particle size does not need to be classified.

Characteristic

1) the fineness modulus of sand is easy to adjust and can be controlled by people (FM = 2.4-3.0 can be achieved in actual production to adjust production);

2) the sand grading is good and the particle size distribution is stable;

3) low production efficiency;

4) high operation cost, large quantities of civil engineering and installation works.

Technological Process

In the process of rod grinding machine-made sand, the open circuit process and wet process are often used.

Generally, the sand making feed bin is set before the rod mill, and the feed bin shall have a certain capacity. Generally, the capacity of the feed bin shall be considered according to the production capacity of one shift of the rod mill. The discharging gallery is set under the feeding bin to ensure the balanced and stable production of the rod mill through the uniform feeding of the vibrating feeder. The mortar milled by the rod mill flows out of the discharge port and enters the spiral grading machine for sand washing. After pre dehydration by the linear vibrating screen, it is sent to the finished sand bin for storage by the belt conveyor.

Feed Particle Size Control

The production test shows that when the feed particle size of the rod mill exceeds 25 mm, the output is higher, but the fineness modulus is larger, and when the feed particle size of the rod mill is less than 25 mm, the effect of the rod grinding machine-made sand is the best. If the modulus of feed particle size is considered, the feed particle size of rod mill shall be controlled within 5-20mm.

Stone Powder Content

Due to the wet production of rod grinding machine-made sand, part of the stone powder is taken away by water during the production process, and the powder content of the final finished sand can only be controlled within 6% – 12% generally, which is undoubtedly suitable for the project with normal concrete as the main project. However, for the main project using RCC, the powder content is obviously not up to the specification requirements.

For the adjustment of stone powder content, the fineness modulus can be reduced and the fine particles can be increased by means of reducing the feeding amount of rod mill and increasing the steel rod amount. The stone powder content of artificial sand can be increased by recycling equipment such as hydrocyclone.

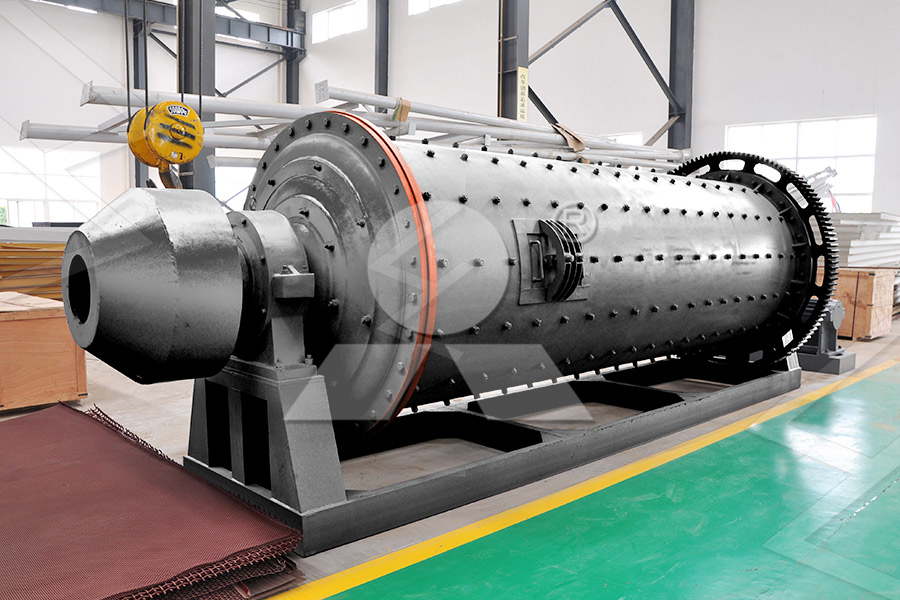

2. Technology Of Vertical Shaft Impact Crusher Sand

The high-speed rotating materials are used to break each other by themselves and friction between materials.

The vertical shaft impact crusher can be divided into “stone striking iron” and “stone striking stone” according to its working mode: the sand making machine impeller rotates at a high speed driven by the motor, throwing materials out of the impeller flow channel and hitting them on the reaction plate. The vertical shaft impact crusher equipped with the reaction plate is called “stone striking iron”; if the reaction plate is not installed, the materials thrown out by the impeller of the crusher will be hit and formed naturally This kind of situation is called “stone striking”. The sand production rate of “stone and iron” is higher than that of “stone and stone”.

Characteristic

The vertical shaft impact crusher sand has the advantages of high production efficiency, good sand particle shape, low operation cost, small amount of civil engineering and installation work, and it can reshape small and medium stones, but it also has the following problems:

1) simple process flow and low unit energy consumption;

2) 5 ~ 2.5mm stone should be broken by repeated circulation, with poor breaking effect and slightly larger energy loss;

3) the grading of finished sand is not ideal, which is a discontinuous grading of “more at both ends and less in the middle”;

4) it is difficult to control the grain size modulus of finished sand (controlled by human factors);

5) the rate of finished sand is low;

6) for normal concrete, the content of stone powder may exceed the standard.

Product Grading and Grain Shape

After the semi-finished crushed stone (particle size 5-40mm) is crushed by vertical shaft impact crusher (stone chipping), its product distribution is: 20-40mm accounts for about 25%, 5-20mm accounts for about 40%, and the sand production rate is about 35%. If “stone and iron” crusher is used, the sand rate can reach more than 50%.

The grain size of the finished sand produced by vertical axis impact breaking is a discontinuous gradation of “more at both ends, less in the middle”. The content of 2.5-5mm is generally more than 32%, which greatly exceeds the range standard of 10% – 25% for medium sand, while the content of 0.63-2.5mm is about 20%, which is seriously insufficient compared with the standard value of about 40%.

Technological Process

There are two ways of vertical axis breaking sand production: open circuit production and closed-circuit production. Each way can be divided into dry process, wet process and semi dry process. In dry production, the sand production rate and stone powder content are high, but the dust pollution is serious. Wet and semi dry production, low sand production rate, easy to control dust.

Many factors need to be taken into account in the selection of dry and wet production methods. When the main project is mainly RCC, it is more suitable to adopt dry production. For the main dust points, parallel dust collection and dust collector can be used to close the vertical shaft broken feed bin. However, for the large-scale artificial aggregate system with normal concrete as the main part of the project, wet production should be adopted.

3. Combined Sand Making Technology

Through the analysis of the sand production law and technological characteristics of rod mill and vertical shaft breaking, it can be found that the sand production rate, fineness modulus, powder content and product grading are all highly complementary. Therefore, the combination of rod mill and vertical shaft breaking can make up for their shortcomings.

Technological Process

After the stone is crushed by vertical shaft impact crusher, it will enter the screening machine for classification. All the stone with a diameter of more than 5mm will return to the transfer bin. The stone with a diameter of 5-2.5mm will enter the rod mill for crushing. After the screw classifier, it will mix with the stone with a diameter of less than 2.5mm and enter the finished product bin.

Characteristic

1) the advantages of vertical shaft impact crusher and rod grinding machine-made sand are concentrated, the disadvantages of vertical shaft impact crusher and rod grinding machine-made sand are overcome, and the problems of small content of medium size sand and excessive loss of stone powder are solved;

2) the quality of finished sand is stable and the grain shape is good;

3) high water and power consumption, high steel bar consumption;

4) large quantities of construction and installation works;

5) the process flow is complex and there are many kinds of equipment.