If you need to make a lot of sand for your business you are going to want to invest in a quality sand making plant. This plant allows you to take rocks and dirt and turn it into sand. You can produce all of the sand you need.

The machine can make other things as well like gravel. The machine is easy to use and it is crucial to have this machine if you need to produce these materials for your construction business.

The machine crushes grit and turns it into sand and plaster. Whether you are using it with rocks or stones, you can rely on the sand maker plant to crush the large materials and process them into grit and stand.

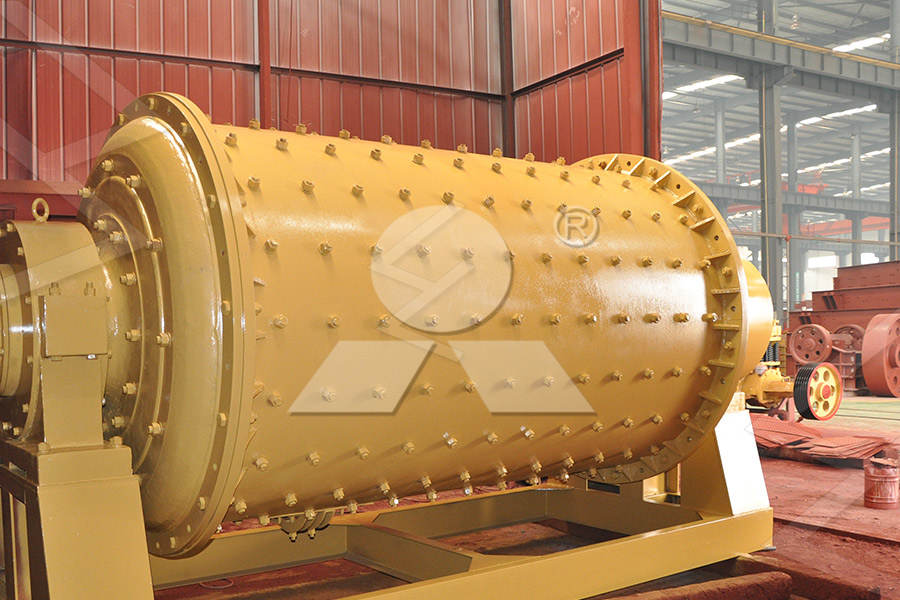

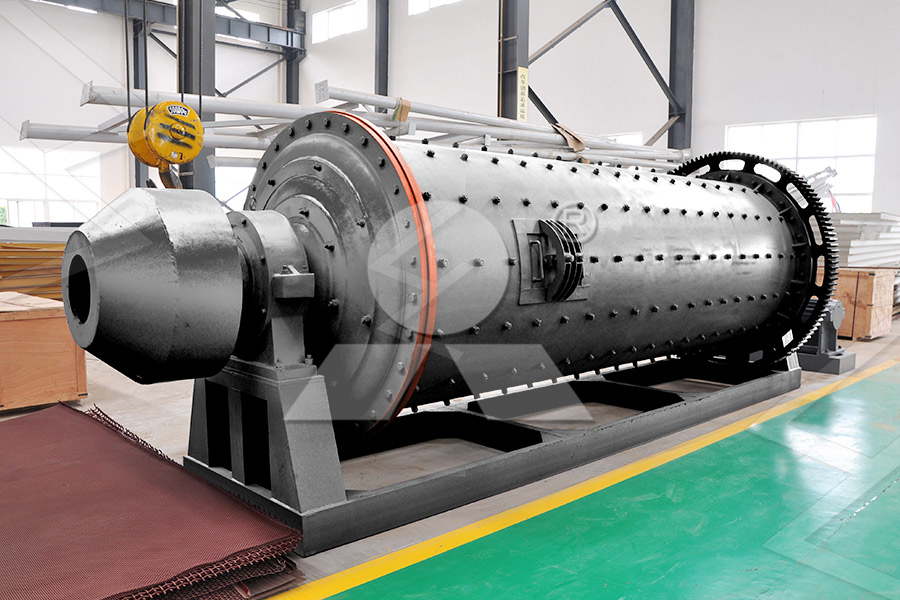

The machine consists of a vibrating feeder that moves the materials into the jaw crusher. Once the rocks have passed through the jaw crusher they go into the impact crusher where the materials are broken down into fine pieces. The vibrating screen screens out the larger pieces so you are left with the grit and sand.