Gold occurs principally as a native metal, usually alloyed to a greater or lesser extent with silver, or sometimes with mercury. Native gold occur as sizeable nuggets, as fine grains or flakes in alluvial deposits, or as grains or microscopic particles embedded in other rocks.

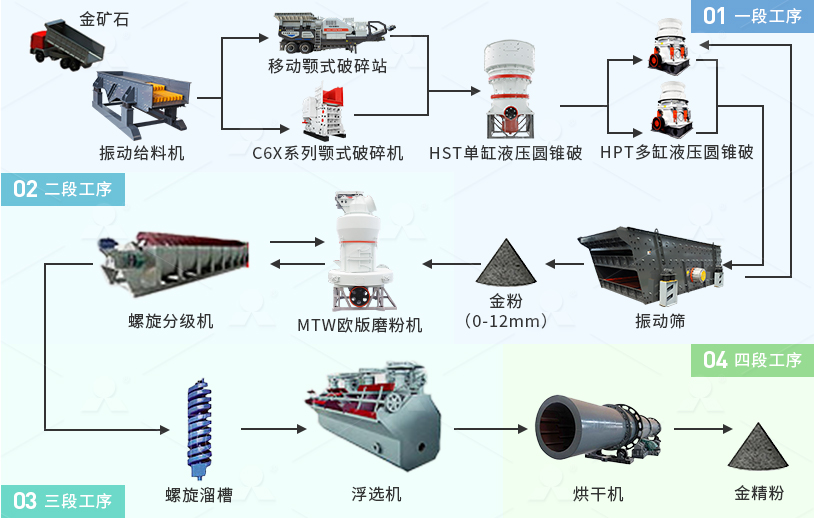

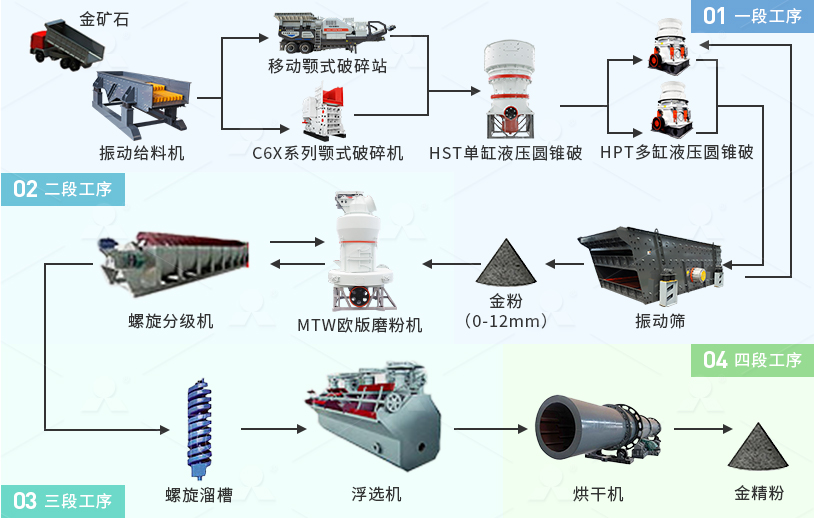

Process flow:

1. Trucks transport the ore from open pits or underground operations to processing operations.

2. Determine the geochemical makeup of the ore, including its hardness, sulfur content, carbon content and other minerals found within, impact the cost and methods used to extract gold.

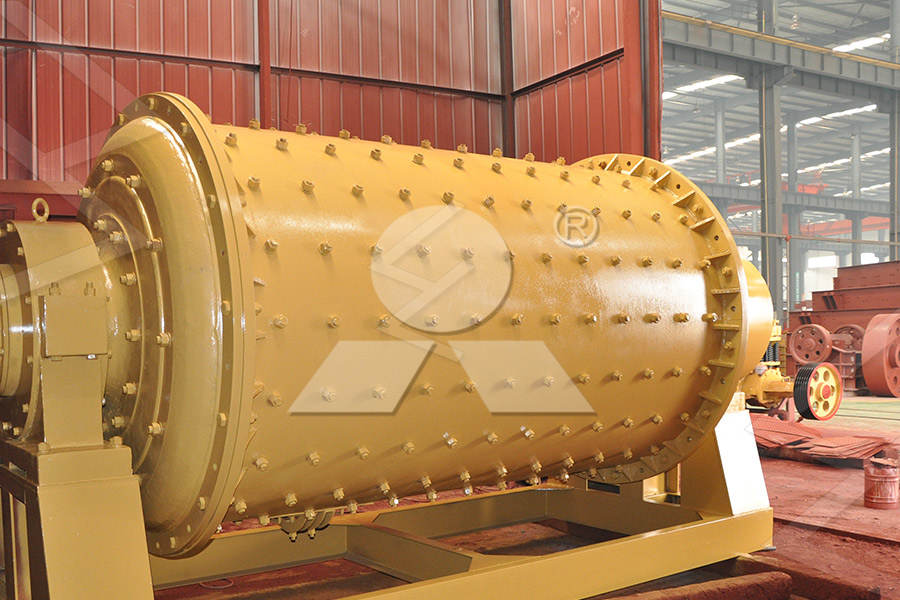

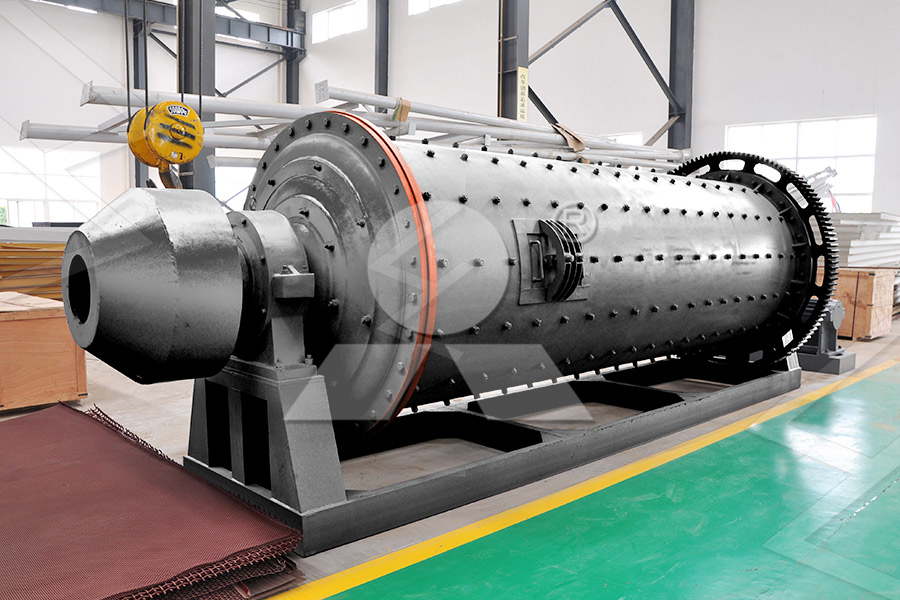

3. Sent gold ore into a series of crushers (jaw crusher, HPT hydraulic cone crusher, etc.) and grinding mills (MTW European version trapezium mill, vertical mill, ball mill, etc.) to reduce the size of the ore particles and expose the mineral.

4. Re-election is widely used in the rock gold mine, as an auxiliary craft, in the grinding process to recover coarse gold, and create favorable conditions to flotation and cyanidation processes, which can improve the beneficiation indicators, improve recovery rate of gold, re-election plays a positive role for increasing production and reduce cost.

5. Flotation process or a weak cyanide solution to the slurry, this process removes up to 93 percent of the gold and 70 percent of the silver from the ore. And then the gold is pulled from the solution and attaches to the carbon. We then "strip" the gold from the carbon by washing it with a caustic cyanide solution. The carbon is later recycled.

6. Next, we pump the gold-bearing solution through electro-winning cells, which extract metals from the solution using an electrical current.

7. Smelt the gold, which melts it in a furnace at about 2,100°F. From there, the liquid gold is poured into molds.

8. We finally send the bars to a refinery for further processing into pure gold.

Applications:

Gold has been widely used throughout the world as money, for efficient indirect exchange (versus barter), and to store wealth in hoards. For exchange purposes, mints produce standardized gold bullion coins, bars and other units of fixed weight and purity.