In granite stone quarrying and mining operation, crushing will be the first processing stage. It is important to know which types of crushers are suitable for granite stone crushing, since choosing right crushing machine can optimize production efficiency and minimize operation cost.

As for granite, due to it hardness, it requires crushing machine which can deal hard stone and rocks. SBM is the professional stone crushing machine manufacturer, we provide jaw crusher, impact crusher, cone crusher and VSI crusher for various types of hard and medium hard stones. Jaw crusher can be applied in primary crushing stage in granite sotne crushing, impact crusher and cone crusher are often applied in second crushing operation, VSI crusher can be used in fine sand crushing applications. SBM experts will design cost-effective crushing solution according to your requirements with lowest cost and price.

Granite Jaw Crusher

Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm. Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable operation process, ultra-low failure rate, and can give full play to the coarse crushing effect of granite. It is an ideal coarse crushing equipment for granite in the current market.

Granite Impact crusher

The impact crusher is usually used for the medium and fine crushing of granite. It is made of extremely good materials in the world. The structure of each component is reasonable, the quality is quite good, the service life is super long, and it has a large processing capacity, high crushing efficiency, Special advantages such as safe and stable operation, low-carbon and environmental protection, have super pertinence and professionalism in the crushing of granite, and occupy a super high share in the crusher market.

Granite Cone Crusher

Cone crusher is another kind of granite quarrying machine which is used as the secondary crusher. SBM HST series Cone Crusher adopts computer optimization design to speed up the speed of main shaft. The unique crushing chamber replace system can quickly replace components in crushing chamber to meet different size requirement.

For high productivity, low operating and wear costs, long service life, and high product yield with desired fines, there’s no better choice than a cone crusher. The cone crusher equipment has proved revolutionary in providing higher capacity and superior product quality, and in providing a wider range of application suitability. From limestone to taconite, from ballast production to manufactured sand, and from small portable plants, cone crushers provide unbeatable performance in secondary, tertiary, and quaternary applications.

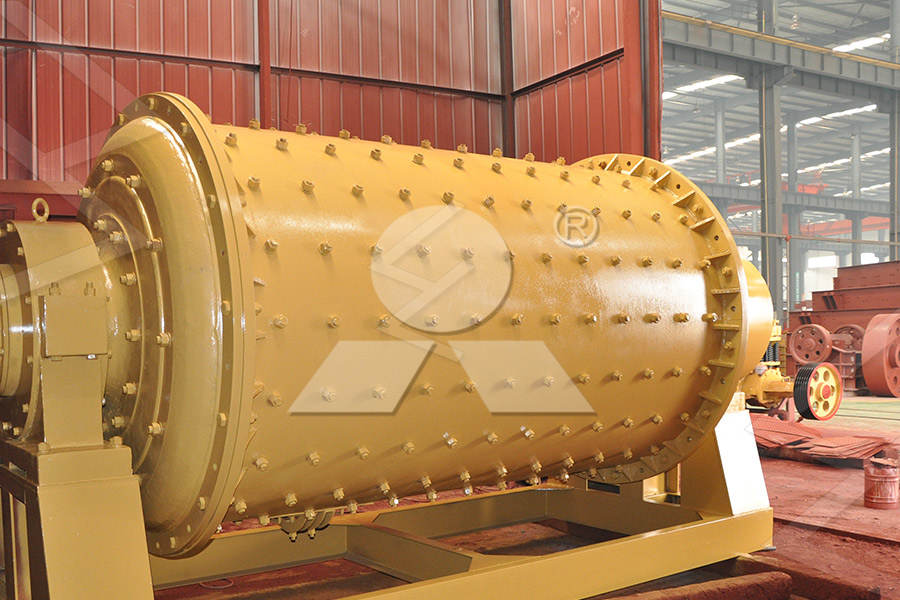

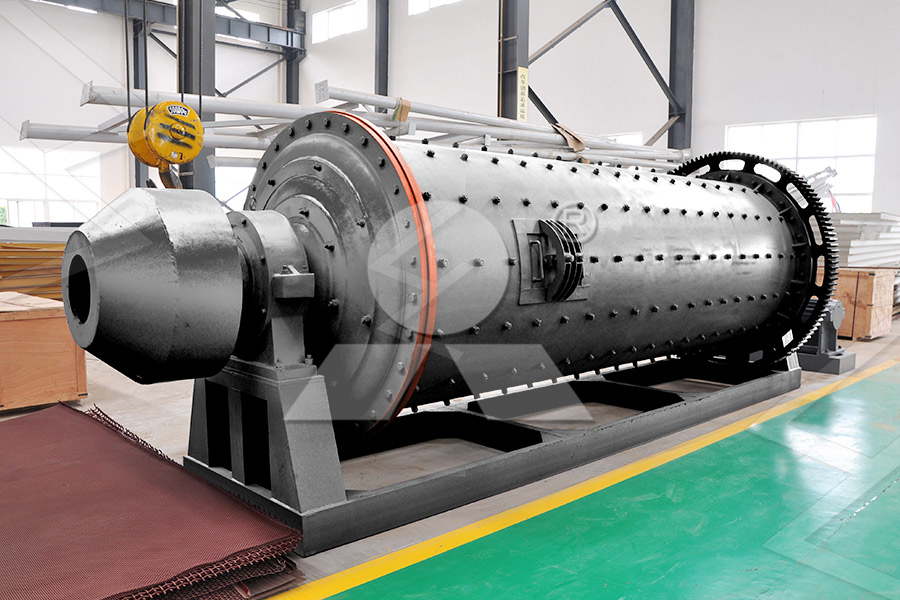

Granite Sand Making Machine

The sand making machine is used to crush granite and make sand. It is an advanced new type of sand making equipment that can be controlled remotely, stable and reliable, and the equipment has strong sealing, not easy to produce dust pollution, and is green and environmentally friendly. It also has the function of shaping, and the finished product has a good shape.

Vibrating Screen

The circular vibrating screen is used for the screening and classification of granite. The materials screened by this equipment are more fine and play an important role in controlling the purity, particle size and quality of finished materials. It has the special advantages of high screening efficiency, high output, strong adaptability, low power consumption and green environmental protection.