Are you in the market for a stone crusher to enhance your construction projects? Installing a stone crusher can be a daunting task, but with the right knowledge and guidance, it doesn't have to be. In this comprehensive guide, we will walk you through the process of installing a stone crusher of capacity 200 tonnes. From considering factors such as cost analysis and selecting the appropriate capacity to actually carrying out the installation steps, we've got you covered. So let's dive in and discover how to make this crucial addition to your construction arsenal!

Overview of Stone Crusher Installation

When it comes to installing a stone crusher, it is essential to have a clear understanding of the process and the various factors involved. The installation of a stone crusher requires meticulous planning and careful execution to ensure that the machine operates efficiently and effectively.

One crucial aspect to consider is the location for installing the stone crusher. It should be strategically chosen based on factors such as accessibility, proximity to raw materials, and potential impacts on surrounding areas.

Another important consideration is determining the capacity of the stone crusher. This will depend on your specific needs and requirements. A higher capacity may be necessary for larger construction projects or if you anticipate processing large quantities of material.

Additionally, it's vital to analyze the cost implications before proceeding with the installation. This includes evaluating not only equipment costs but also expenses related to materials, labor, and any additional infrastructure required.

By carefully assessing these factors upfront, you can better plan your budget and avoid unexpected surprises during installation. Remember that investing in quality equipment from reputable manufacturers can save you money in the long run by reducing maintenance costs and improving overall productivity.

In conclusion (not concluding), successfully installing a stone crusher involves considering several key aspects such as location selection, capacity determination, and cost analysis. By taking these considerations into account during each step of the process – from site preparation all the way through testing – you'll ensure a smooth installation that delivers optimal performance for years to come. So let's dive deeper into each stage now!

Factors to Consider for Stone Crusher Installation

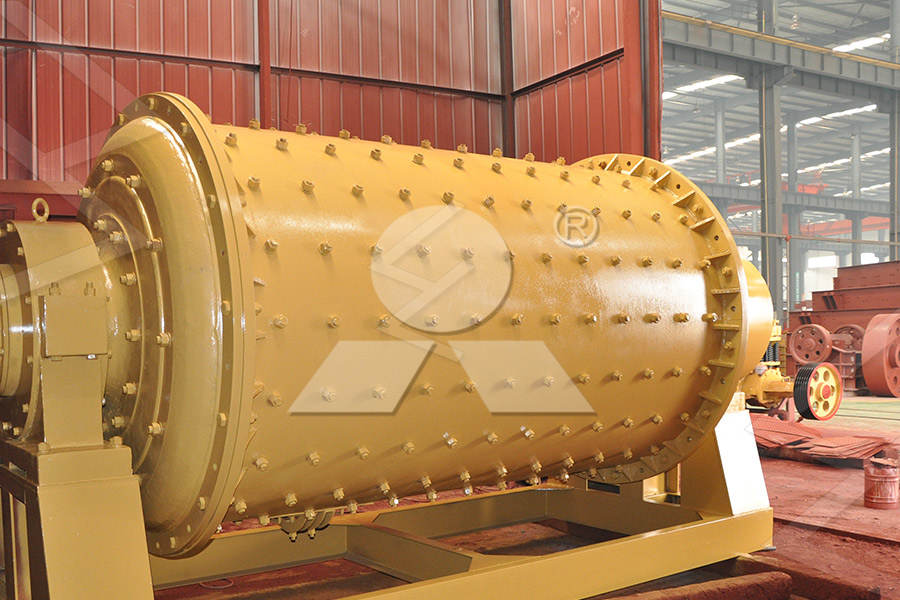

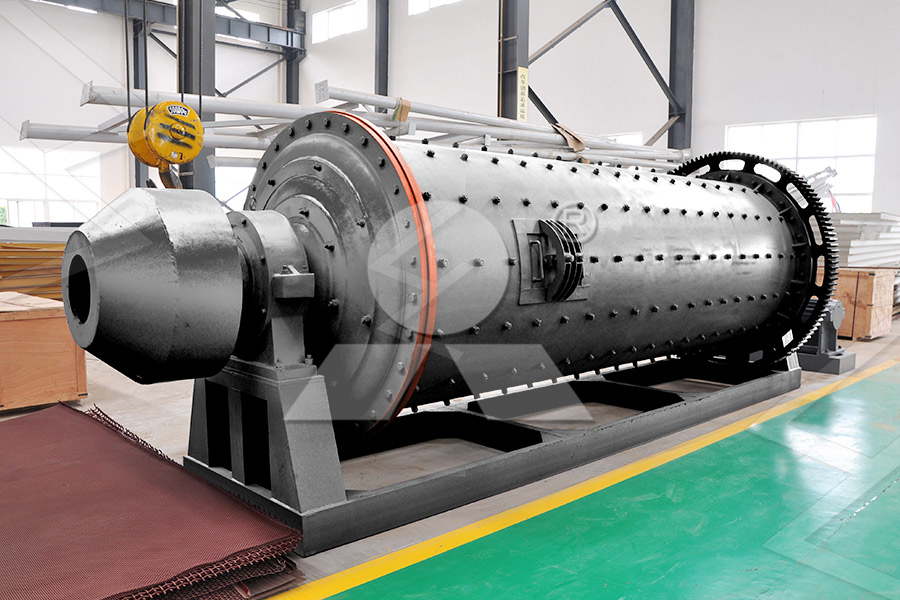

When it comes to installing a stone crusher, there are several factors that need to be considered. First and foremost is the type of stone crusher machine you choose. Different machines have different capacities, so it's important to select one that meets your specific needs.

Cost Analysis for Installing a Stone Crusher

When it comes to installing a stone crusher, cost analysis plays a crucial role in determining the overall budget of the project. It is essential to consider various factors that can impact the installation cost and make an informed decision.

Selecting the Capacity of the Stone Crusher

Selecting the capacity of a stone crusher is a crucial step in the installation process. It determines how much material the crusher can handle at any given time, which directly affects its efficiency and performance.

Determining the Cost of Materials and Equipment

Determining the cost of materials and equipment is a crucial step when installing a stone crusher. It involves carefully assessing the requirements and specifications of the project to ensure that you have all the necessary resources in place.

Steps to Install a Stone Crusher

Preparing the Installation Site

Excavating and Preparing the Foundation

Setting the Stone Crusher in Place

Connecting the Required Power Supply

Testing and Fine-Tuning

Preparing the Installation Site

Preparing the installation site for a stone crusher is an important step that should not be overlooked. It sets the foundation for a smooth and successful installation process. Before you begin, it's crucial to assess the area where the crusher will be placed and make any necessary preparations.

Excavating and Preparing the Foundation

Excavating and preparing the foundation for a stone crusher is a crucial step in the installation process. It sets the stage for proper support and stability of the crusher, ensuring its long-term performance.

Setting the Stone Crusher in Place

Now that you have prepared the installation site and excavated the foundation, it's time to set the stone crusher in place. This step is crucial for ensuring that your crusher functions properly and efficiently.