Physical properties of river sand

The Philippine is located on the western edge of the Pacific Plate, where there are frequent earthquakes and volcanic activities.

A large number of hard rocks are produced accompanied by the volcanic eruption, they have been impacted for a long time, and they are smooth in surface and contain less impurities. The buildings which used river sand in some reinforced concrete structures can extend their life expectancy and have stable mechanical properties.

Layer structure of river sand

The Philippine river sand is composed of conglomerate, sandstone, shale, basalt, tuff and a small amount of limestone. The solid concrete made of these sands always has uniform texture and physical strength because of the uniform size and hard physical structure.

The mud content of river sand

As mentioned above, the Philippine river sand is mainly produced by the long-term effects of volcanic eruptions, crustal movements and river impacts. For the stratums where river sand stored in are stable, there is only fewer volcanic ash in the sand. So, it’s easy to remove the mud from the sand, and the cost of processing is low.

The chloride ion content of river sand

Because most of the Philippine river sands are collected from the riverbed generated after the volcanic eruption, the colors of the Philippine river sand mostly are black or gray.

The chloride ion content is relatively low. North and central parts have the lowest chloride ion content, below 0.02% on average. It is in line with the international standard for the use of concrete in river sand.

River sand particle size

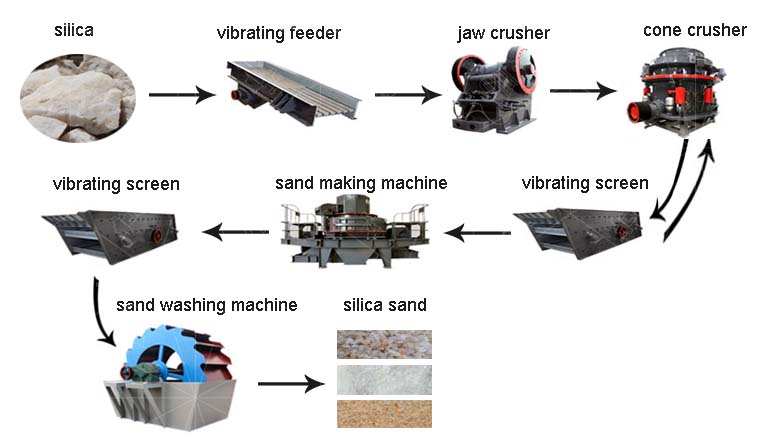

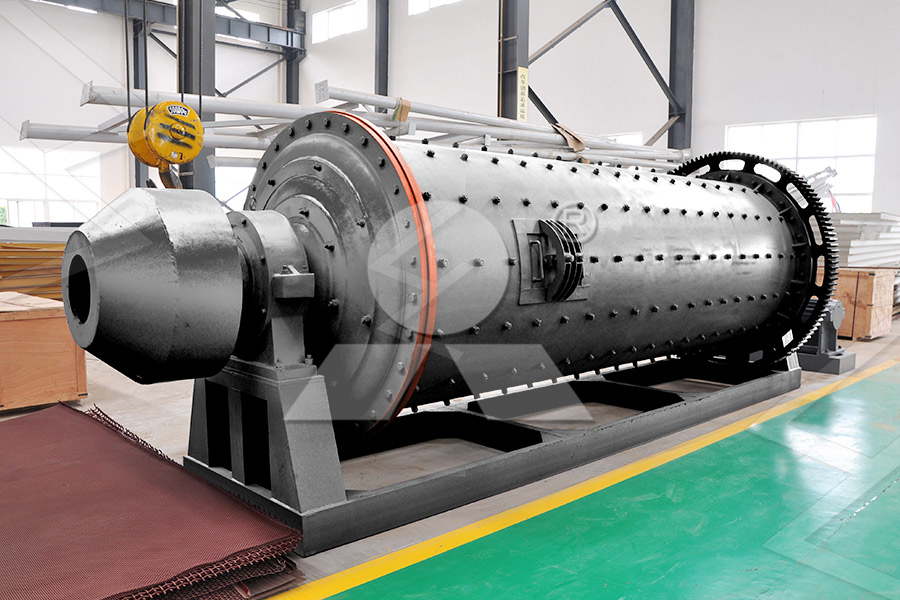

With low mud content, Philippine river sand can be directly used as building materials after simple sieving. However, some river sands in other regions are mainly larger river pebbles, then a crushing machine is recommended.

The hardness of river sand

The main component of river sand is quartz, so its Mohs hardness is 7. It can be used by mixing with other materials for its good hydrophobic and air permeability.

Based on the above analysis, the river sand in the Philippines has unique advantages in the construction of the river sand supply market due to its low mud content, low chloride ion content, high hardness and perfect particle size which is suit for construction.

The quality of the Philippine river sand is extremely high. The only drawback is that it contains less large gravel, which is not convenient for direct use as construction sand. Therefore, a screening process is needed. Good screening equipment will certainly do more with less for the huge market demand.