Rock and crushed stone products will be initially taken away from the deposit by drilling and blasting, after which carried for further processing application. Techniques employed for rock extraction vary because of the property and location of the deposit.

The rock and stone processing mainly include crushing, grinding, screening, size classification, material handling and storage process. The screens separate large boulders from smaller rocks which don’t need primary crushing, therefore decreasing the load to the primary crusher.

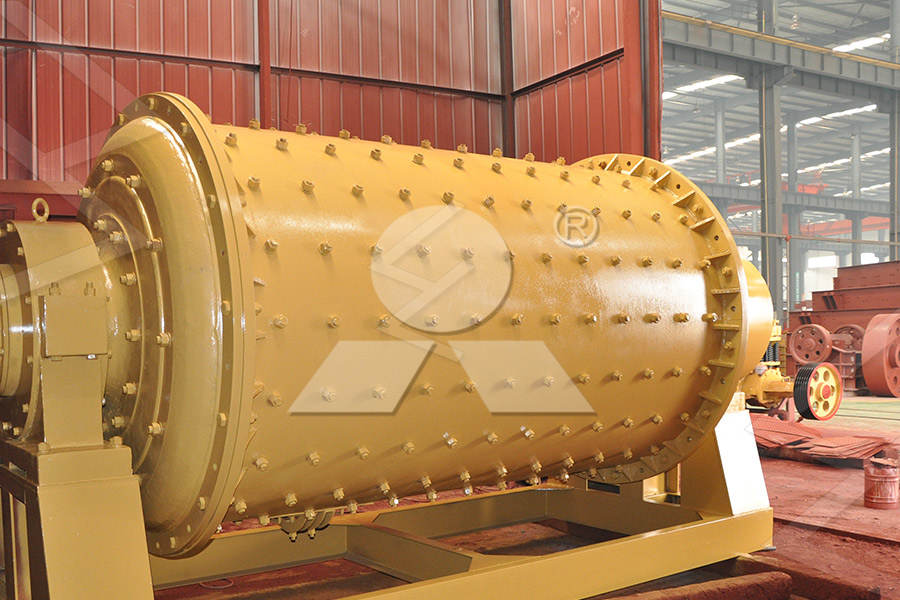

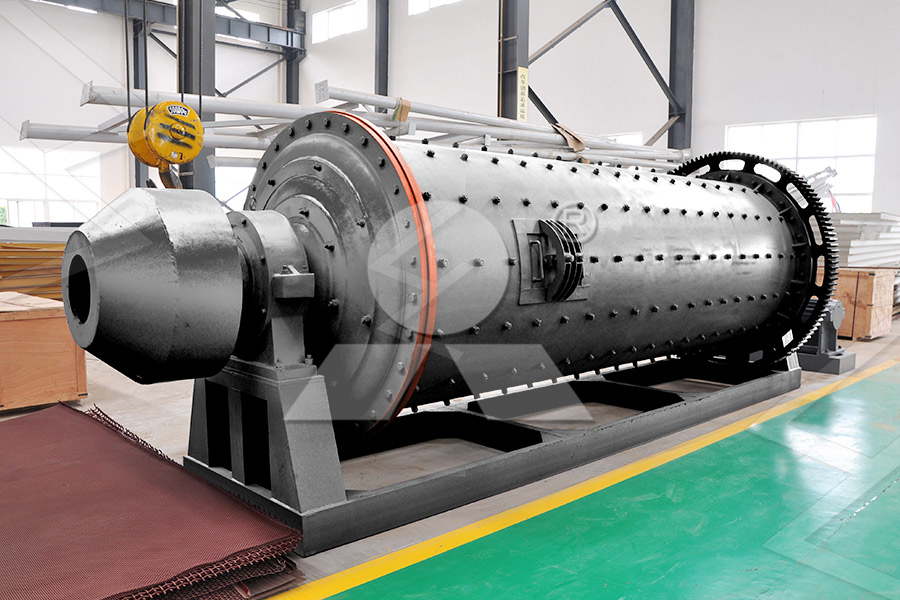

As a leading company of mining equipment manufacturing, Zenith is specializing in the design and manufacture of crushing equipment, grinding equipment, sand making equipment and beneficiation equipment. The machines designed by our company are of high quality and competitive price. The mobile crusher for sale is widely used in many countries and were well received by the mine owners and quarry operators. Our mobile crusher for sale aims at satisfying the ever increasing crushing demand. It is designed based on the conception of fully adapting various crushing condition, eliminating obstacles caused by location, environment, consequently providing simple, efficient, low-cost crushing equipment.

Dawn’s portable crushing plant is a newly designed rock crushing & screening plant, which is flexible, convenient and strong mobility, can save a large construction capital and relocation. Raw materials can be reduced at the mine site without being transported again, and also can be moved with the promotional exploitation of the raw material, which saves a large number of transportation costs. zenith company specializes in producing crusher, screen, transportation, and other rock breaking and minerals processing equipment. On the basis of the licensed technology, we optimize and introduce newly two large and three small series crushing and screening equipment.