The market share of Raymond mill is increasing under the drive of technology. Why can Raymond mill be so popular in the market? The reason for this is that Raymond mill can fulfill these high requirements for the production of some high-granularity grinding powder. In addition, on the premise of ensuring the power of Raymond mill, the equipment can still achieve environmental protection and energy saving.

After years of practical experience and continuous improvement of design, the overall structure of Raymond mill continues to improve. At present, Raymond mill has been widely used in mining, metallurgy, chemical industry, building materials and other fields. It is suitable for processing materials with Mohs hardness of 7 grades and humidity of less than 6%, such as limestone, marble, gypsum, barite, kaolin, bauxite and so on. The fineness of finished products is between 70 meshes and 325 meshes.

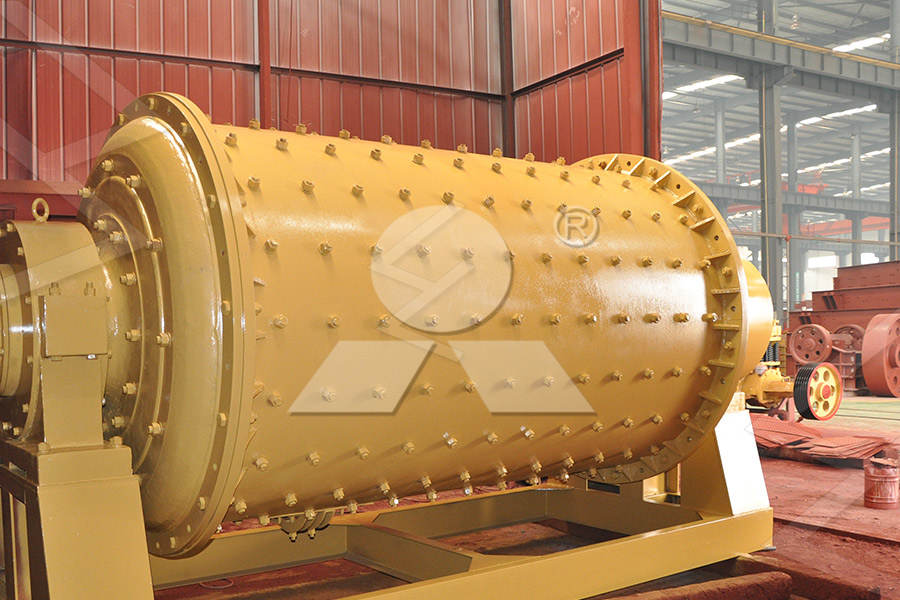

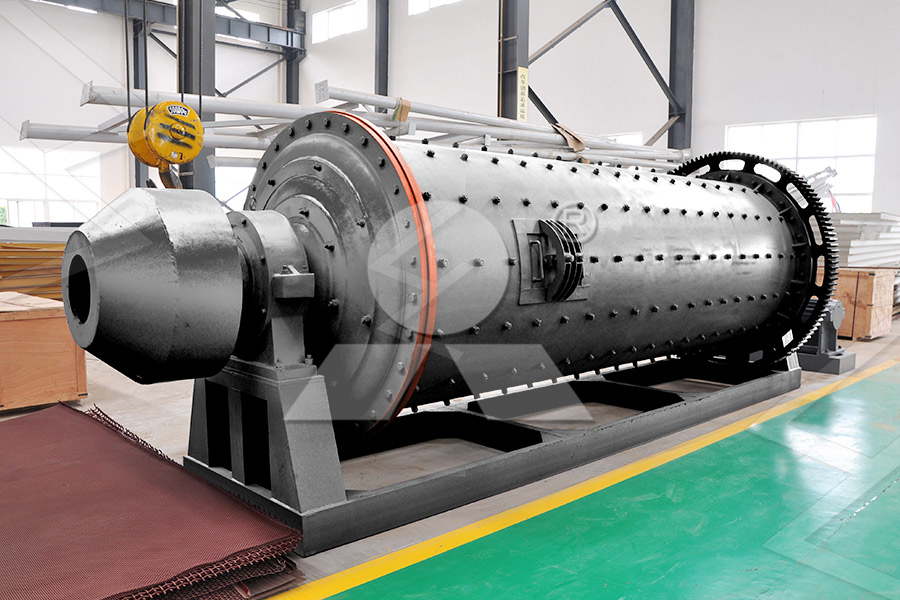

The whole set of Raymond mill consists of main engine, analyzer, blower, separator, bucket elevator, vibration feeder and electronic control equipment. The main machine of Raymond mill covers an area of filial piety. The whole equipment is a complete system. It can independently complete the processing of raw materials, the packing of finished powder, the uniform sieving rate of finished products, the wear resistance of wear-resistant materials, reliable operation, less pollution of environmental protection dust and low working noise.

In recent years, with the development of science and technology in our country, the level of our grinder is constantly improving. Raymond mill, as a common and widely used grinder equipment, can reduce electric energy and improve economic efficiency by replacing the roll copper sleeve in the production process on the premise of ensuring the power of Raymond mill. In addition, the differential drive can also be changed under the premise of ensuring the same power of Raymond mill, which can reduce pollution and noise, improve speed and accuracy, change the transmission of chain drive tooth belt, and help maintain the cleaning and maintenance of ultrafine grinding.

For enterprises, the power of Raymond mill is the guarantee of production efficiency, and energy saving and environmental protection is to respond to the call of the state to reduce the pollution of Raymond mill. So in the production process of Raymond mill, it can be moderately adjusted to make the production more environmentally friendly and efficient.